Data in Operational Technology

The Potential of Automation

Operational technology (OT) in our manufacturing plants, vehicles, and machines with digital sensors is generating thousands of terabytes of data every day. Where is it all going?

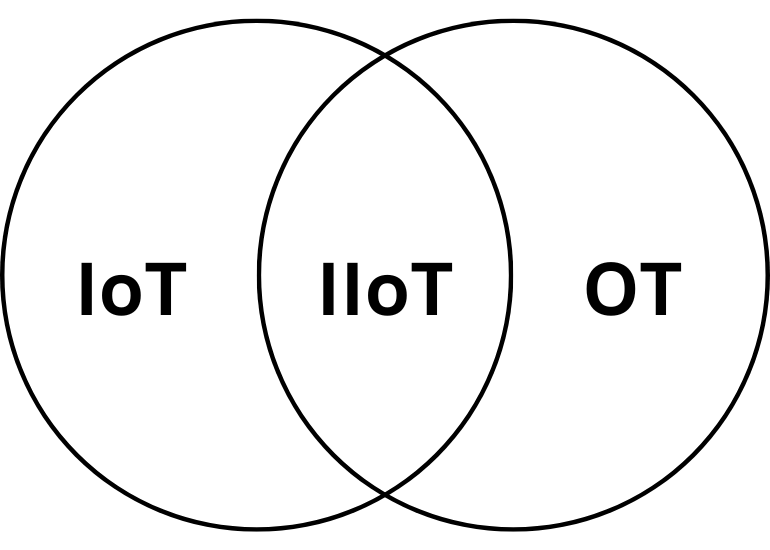

Most of this data is not being stored long term. Instead, it is often used solely for the immediate functioning of the device or system that generated it, without being integrated into larger operational processes. In a time when people are saying that data is the new oil, this seems like an obviously missed opportunity. The rapidly evolving capabilities of the internet of things (IoT) and OT are paving the way for greater data use. However, to leverage these technologies effectively, organizations must find ways to capture data, integrate that data, and finally automate larger processes.

What is OT?

Operational Technology (OT) is the hardware and software used to monitor or control physical devices, processes, and events on various machines and structures. OT includes advanced manufacturing equipment, vehicles fitted with digital sensors, sensors on the transportation grid, and even complex military weapon systems. Yet most OT data is just now being realized as OT converges with the Internet of Things (IoT) and creates the Industrial Internet of Things (IIoT).

Traditionally, the data from OT was not stored long term or transferred to the internet. This fact becomes obvious when thinking about the data from an engine control unit (ECU) on a 2000 Chevrolet versus how data on a brand new Tesla is used today. This convergence with IoT is enabling “smart” equipment, vehicles of all types, and even cities to achieve a level of interconnectivity and data exchange that was previously unimaginable. This convergence is often referred to as the fourth industrial revolution or the buzzword “Industry 4.0”. IIoT is the new portion of the internet that is driving this revolution.

OT Data Today

OT is not just in our manufacturing plants and vehicles but has permeated into almost every aspect of our lives. OT sensors are embedded in many different systems and generate a ton of underused data. These range from HVAC sensors to accelerometers in vehicles, vibration sensors in manufacturing machinery, and flow meters in water treatment plants. Each sensor generates its own unique type of data, which is directly linked to the system's operational state.

Today, there are tons of ways to get data off of OT. For example, supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and distributed control systems (DCS) are all used to monitor and control OT systems. They are capable of collecting data from a large variety of sources and transmitting it to the cloud for analysis. With the advent of IIoT, even more data links are becoming available. IoT devices can connect to the internet and transmit data in real-time, enabling remote monitoring and control.

For instance, an industrial cooling system might have sensors that generate real-time data on the coolant's temperature. This data is crucial for maintaining optimal operating conditions and preventing overheating. Modern transportation systems are also increasingly adopting OT. Vehicles were already fitted with a variety of sensors that monitor everything from engine performance to fuel efficiency, but now these vehicles are collecting data to understand factors like driver behavior. This new data is being sent back to the cloud and used to manage large scale logistics. In cities, OT data is being used to manage and optimize everything from traffic signals and public transportation to power grids and waste management systems.

However, most of these data links are still underutilized. For example, in a manufacturing plant there might be hundreds of different sensors generating unused data. If this data is not stored and analyzed, it's like having a goldmine and not mining it. Instead of just using data for immediate operational needs, organizations should also save it and use advanced analytics to improve operations.

Easy Applications of OT Data

There is a wide range of potential applications for leveraging OT data in an business or supply chain. Yet most organizations are still in the early phases of collecting and organizing their data.

Data warehouses provide a central repository for not only business data but also data from OT systems. These databases allow organizations to keep a historical record of their operations and facilitate the analysis of long-term trends. The data can be organized, analyzed, and visualized to provide insights to drive decision-making at multiple levels. With business intelligence (BI) applications, OT data can be transformed into easy-to-understand reports, and dashboards. For instance, manufacturing managers use BI applications to visualize data from production line sensors to identify bottlenecks and optimize the production process.

One of the most impactful applications of OT data is for predictive maintenance. By analyzing data from machine sensors, organizations can predict when a machine is likely to fail and schedule maintenance accordingly. This not only prevents unexpected downtime but also optimizes the use of resources. Data-driven predictive maintenance programs extend the life of machinery and help minimize replacement costs.

OT data is also useful in operations and strategy. Logistics organizations can use data from vehicle sensors to forecast fuel consumption and plan fuel purchases. Similarly, a utility company can analyze data from smart meters to forecast electricity demand and optimize the power supply. By analyzing data from a production line, manufacturers can identify inefficiencies and devise strategies to improve productivity. OT data even informs strategic decisions, from where to invest in new equipment to how to alter supply chains. This data helps to understand processes better and know where improvements should be made.

What is State of the Art?

Some new applications of OT data are transforming industrial operations and the larger economy.

In the automotive industry, companies like Tesla, BMW and Mercedes are already leveraging OT data to revolutionize the driving experience. Vehicles now have sensors that monitor everything from engine performance to driver behavior. This data is used to optimize vehicle operations, provide real-time diagnostics, and even enable autonomous driving. For instance, Tesla's Autopilot system uses a combination of cameras, radars, and ultrasonic sensors to collect data about the vehicle's environment. This data is processed in real-time to control the vehicle's speed, steering, and braking, allowing semi-autonomous driving.

The manufacturing sector is perhaps the most prominent user of OT data for automation. Manufacturers are using a variety of sensor data to automate their production lines. Manufacturing giants like Fanuc are combining robotics, automation, and advanced analytics to provide IIoT offerings. Sensors monitor the production process and feed data into control systems that adjust the operations in real-time. This not only increases efficiency but also improves product quality by reducing human error. Plants are using sensors to monitor equipment in production lines, enabling real-time adjustments and predictive maintenance. This technology not only increases efficiency but also reduces downtime and extends the life of machinery.

Highly regulated industries are even catching on. In the energy sector, IIoT is used to automate and optimize the generation, distribution, and consumption of energy. Everything from power plant performance to consumer energy usage is being monitored. IIoT is also improving patient care. Sensors are used to monitor patient vitals to medication adherence, enabling real-time adjustments. This not only improves patient outcomes but also lowers healthcare costs.

Even companies in older sectors are using OT data to not only optimize but automate processes. In farming operations, sensors monitor soil moisture levels and crop health. This application increases crop yields and reduces water and fertilizer overuse. Sensors are already embedded in all kinds of machinery including Deere and Caterpillar to monitor operational parameters such as temperature, pressure, and vibration. The data from the equipment is used for maintenance, anticipating failures and automatically scheduling services. This reduces downtime and extends the life of the machinery. Caterpillar has been developing advanced GPS integrations and remote control for a long time. This data collection has enabled them to continue to automate even more features.

An emerging application of OT data is the concept of digital twins. These are virtual replicas of physical systems that uses real-time data to mirror the system's state. For example, a digital twin of a manufacturing plant uses data from various sensors to simulate the plant's operations. The twin also allows managers to test different scenarios and strategies without disrupting actual production. It provides a platform for training employees and planning future expansions. Nearly full process automation in coordination with digital twins is becoming a reality thanks to the integration and advanced use of OT data.

Disadvantages

While the advantages of leveraging OT data are obvious, there are still some big challenges. These range from capture and storage to processing and integrating the data.

Sensor Expense and Reliability: Some sensors for specialized equipment are pricey and unproven. Their reliability varies and most of the companies who produce them are fairly new. It is also difficult to judge the accuracy of the data collected. A faulty sensor can create incorrect data, causing costly mistakes.

Diverse Protocols: OT systems use a wide range of protocols, and many are industry-specific or proprietary. This diversity makes it challenging to integrate the size and complexity of OT data into broader IT systems, requiring specialized interfaces and middleware.

Difficulty Storing and Using the Data: The sheer volume of data generated by OT systems is overwhelming. Storing, managing, and analyzing this data requires significant infrastructure and expertise, which is costly and complex for most organizations. Extracting meaningful insights from the data usually involves advanced analytics, requiring specialized skills and software.

Interconnectivity: While interconnectivity can enhance the value of OT data by allowing for real-time analysis and control, it also increases complexity. Managing communication between different OT devices and systems can also be a major technical challenge.

Cybersecurity: As OT systems become more interconnected, they create additional attack vectors for cyber threats. Unauthorized access to data on sensitive equipment or critical infrastructure can lead to serious problems, including operational disruptions, financial loss, and reputational damage. Robust security measures are needed and being developed to protect OT data.

Unproven Cloud Services: While cloud services offer a promising solution for integrating OT data, many of these services are still relatively new. Organizations leveraging cloud services often have issues with reliability, security, and compatibility among IT and OT systems.

Next Steps

The potential applications of OT data are pushing many organizations to overcome the implementation challenges. Here are the steps to take to for leveraging OT data effectively.

Find the low hanging fruit. Start small. Begin by identifying a single process or piece of equipment where operational data can easily be integrated. Bringing in new data should be an iterative process.

Find cheap, reliable sensors and experiment. There are many cost-effective options on the market for sensors and services. A lot of organizations are just using a cheap Raspberry Pi with basic vibration sensors to start gathering data from machines. The key is quickly researching and testing different options to see what meets your needs. Once you've found usable data, experiment with integrating it into your operations.

Aggregate to a data warehouse. As OT data is collected, you'll need a place to store and analyze it. This is where data warehousing and BI come into play. A data warehouse or lake provides a central repository for storing the data, allowing for historical record-keeping and trend analysis. BI tools can then be used to analyze this data, providing insights that drive process improvement.

Develop a long-term automation plan. Start developing a long-term plan for integrating OT data into your operations with the goal of automating processes. This plan should consider the technical challenges you'll face, including managing the volume of data, ensuring interconnectivity, and protecting against cybersecurity threats. The ultimate goal of leveraging data is to transform your organization’s operations. By doing this effectively, you will increase efficiency, improve quality, reduce downtime, and even automate entire processes.

While the integration and use of OT data present large challenges, success offers far more significant opportunities. By taking manageable steps, investing in data management infrastructure, experimenting with reliable technology, and developing a long-term plan, your organization can leverage OT data to drive innovation and growth.